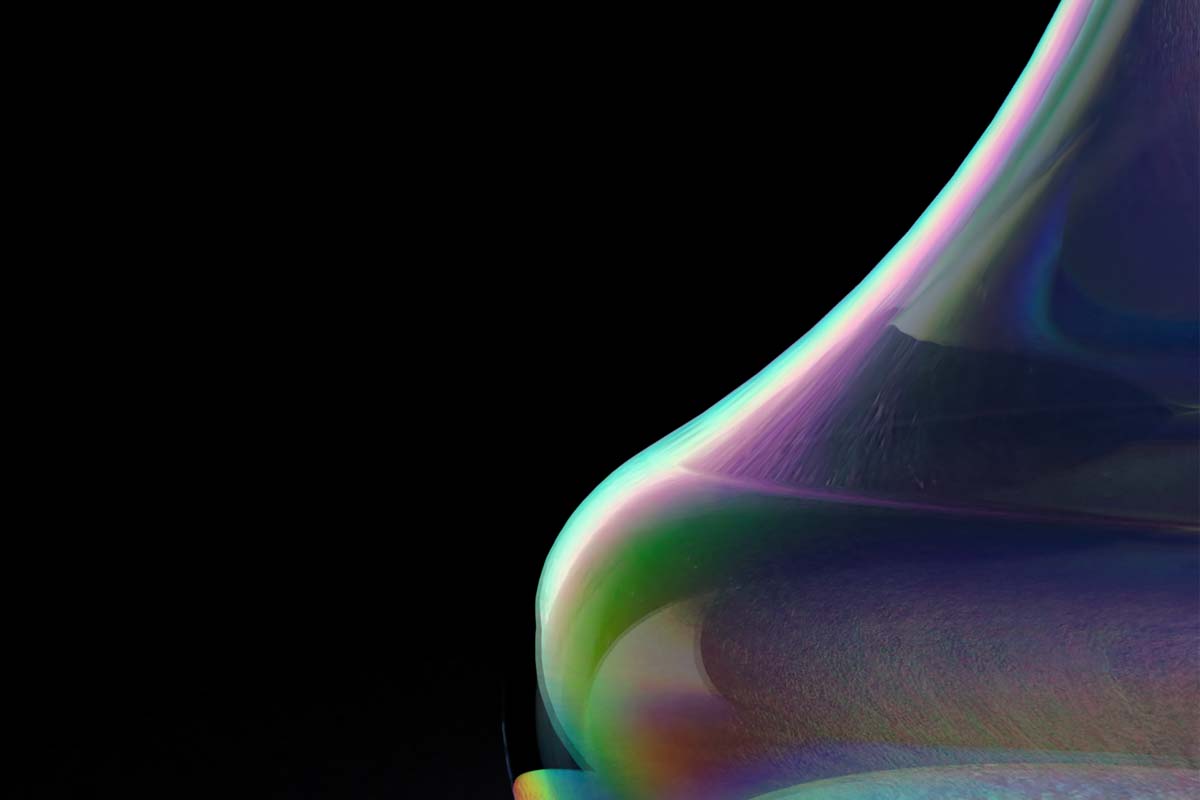

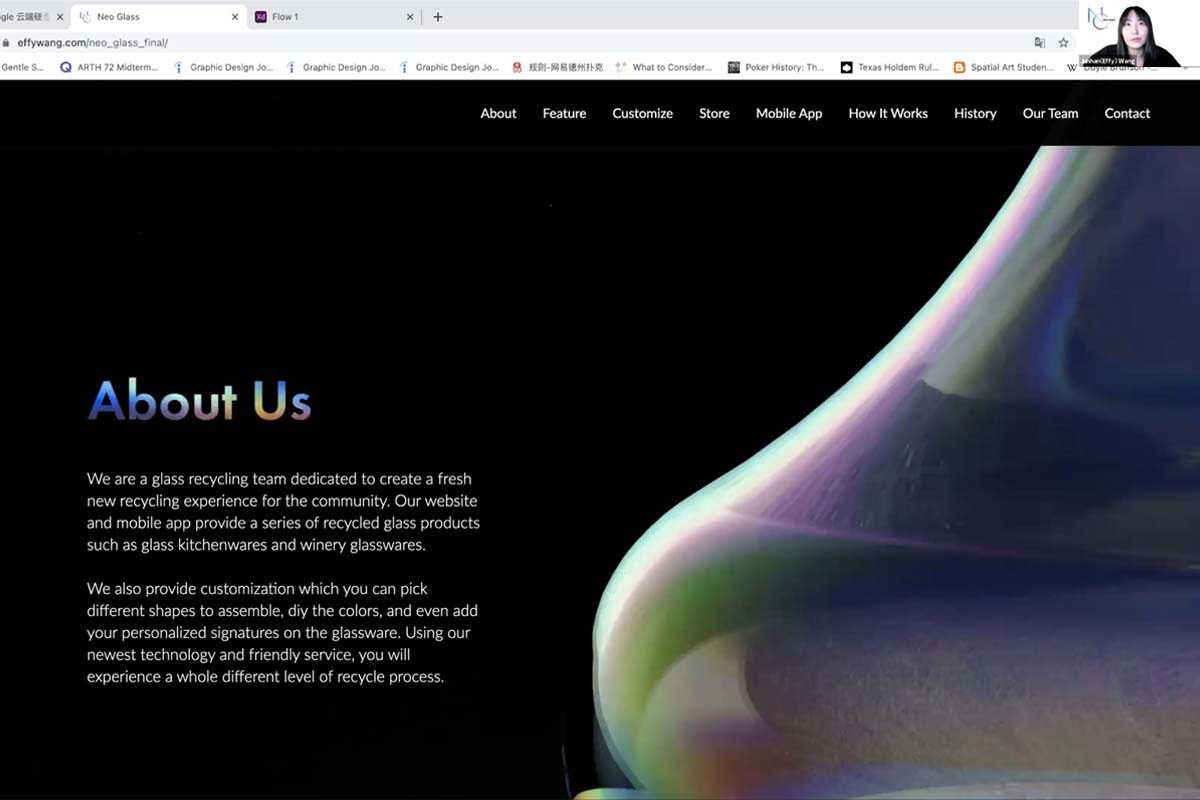

Neo Glass

Designers

Effy Wang, Tina Sun, Lydia Lim

Engineers

Pourya, Saket, Nick

A 3D printing machine which melts and regenerates old glass into 3D printing materials for new glass products using the sand sintering additive manufacturing process.

Proposal Presentation

Neo Glass addresses the environmental and economic impact of wasted glass by making recycling more fun.

Final Presentation

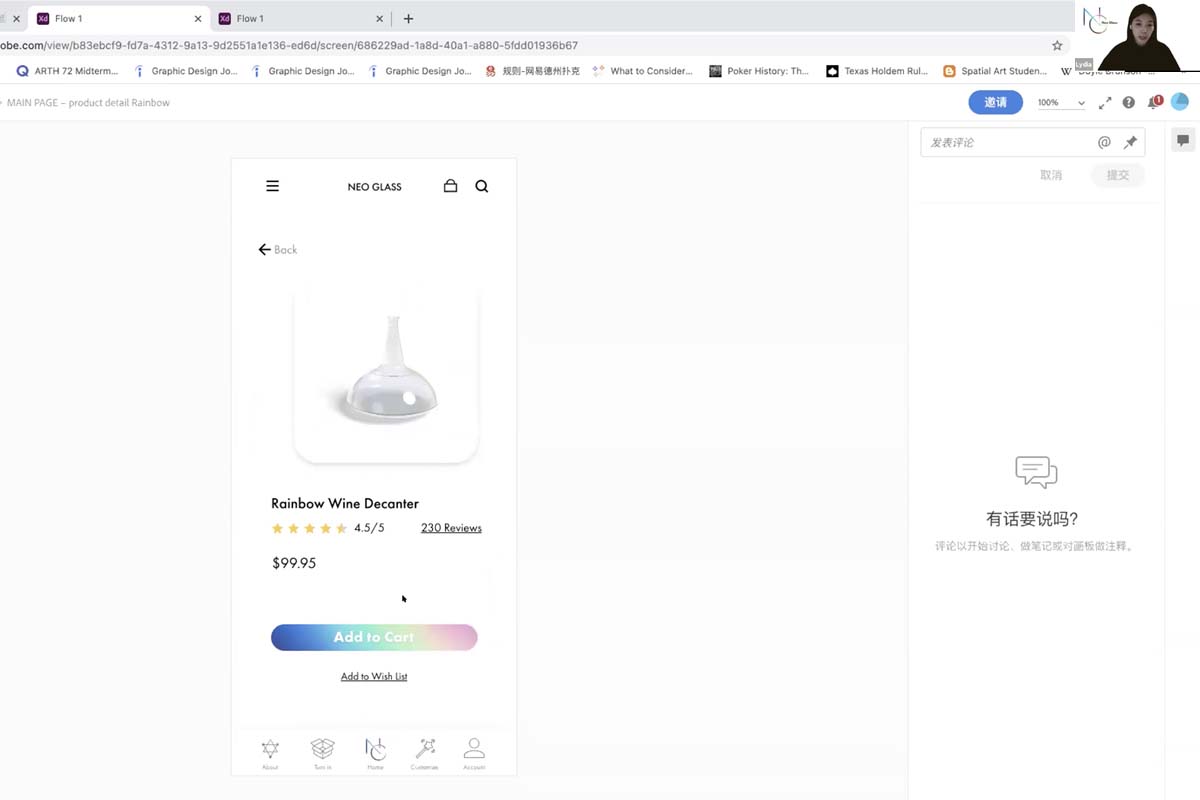

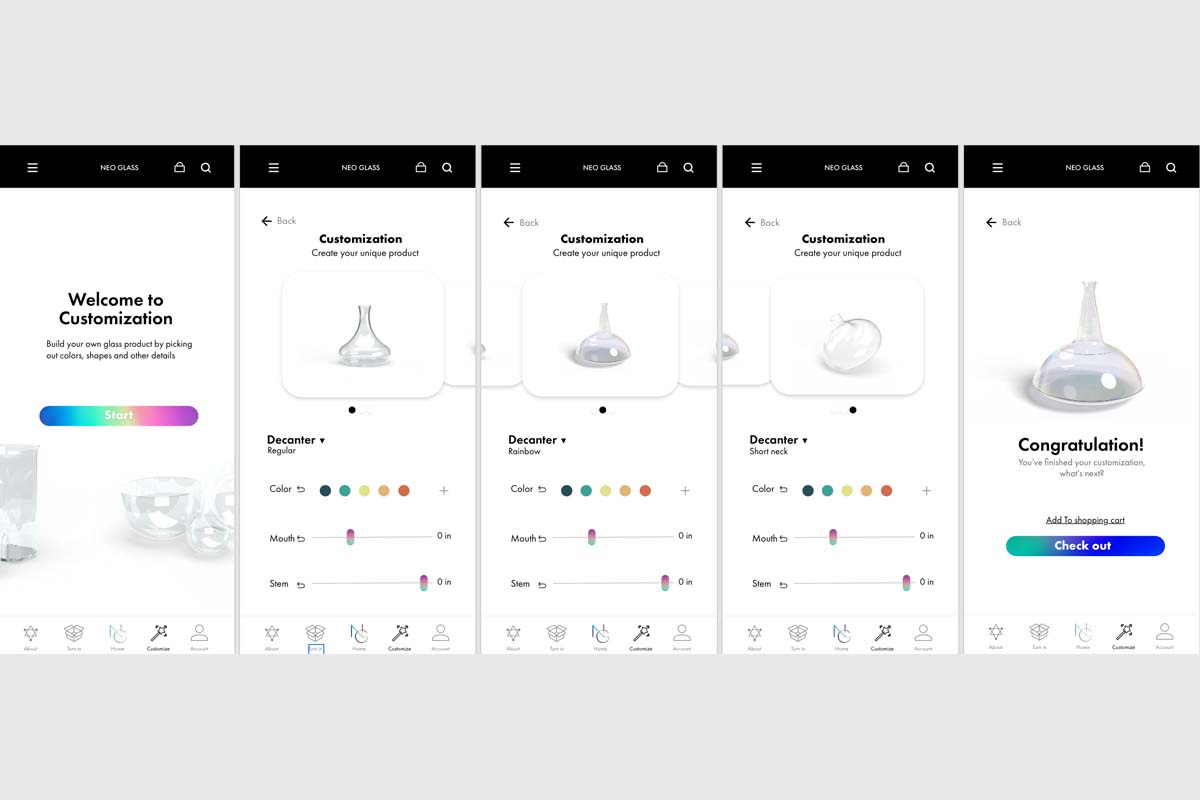

Glass products and wine decanters can be customized according to shape and color, and then purchased through the Neo Glass mobile app.

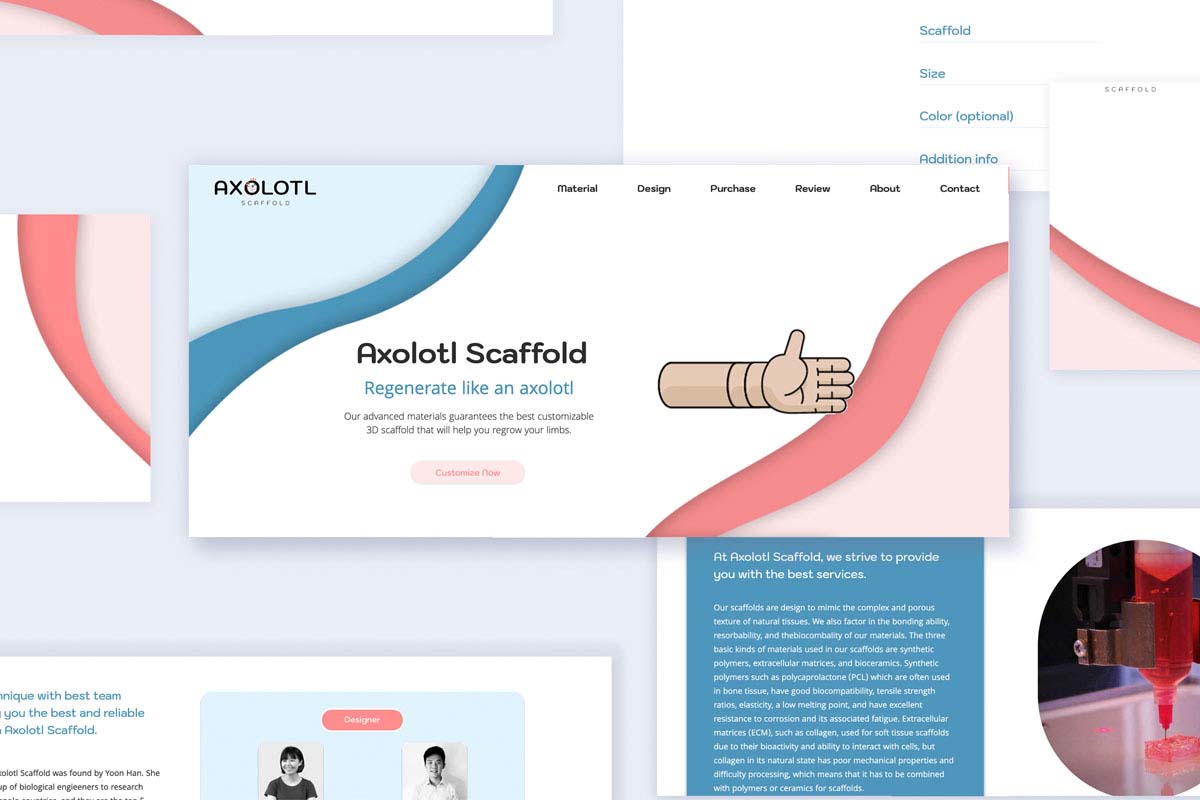

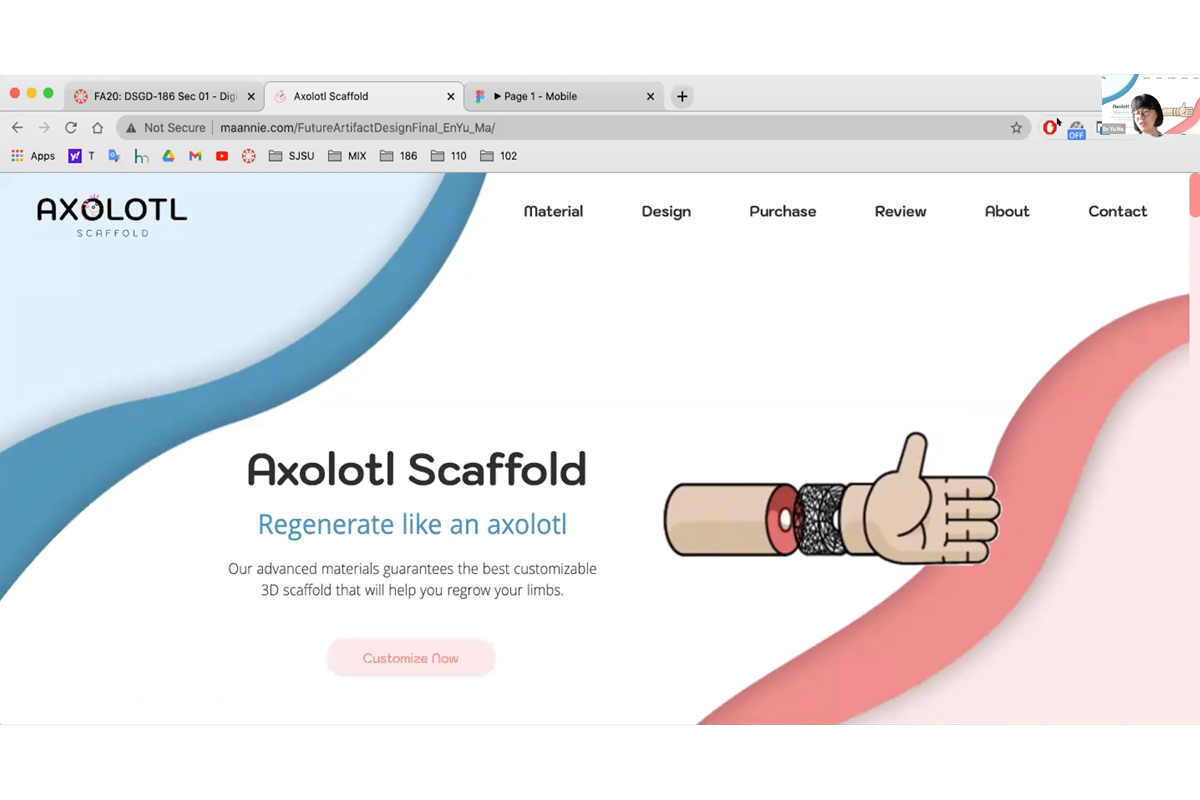

Axolotl Scaffold

Designers

En Yu Ma, Phi Ho

Engineers

Jazmeen Ravendran Pillay, Lianne Posadas, Manpreet Dhariwal

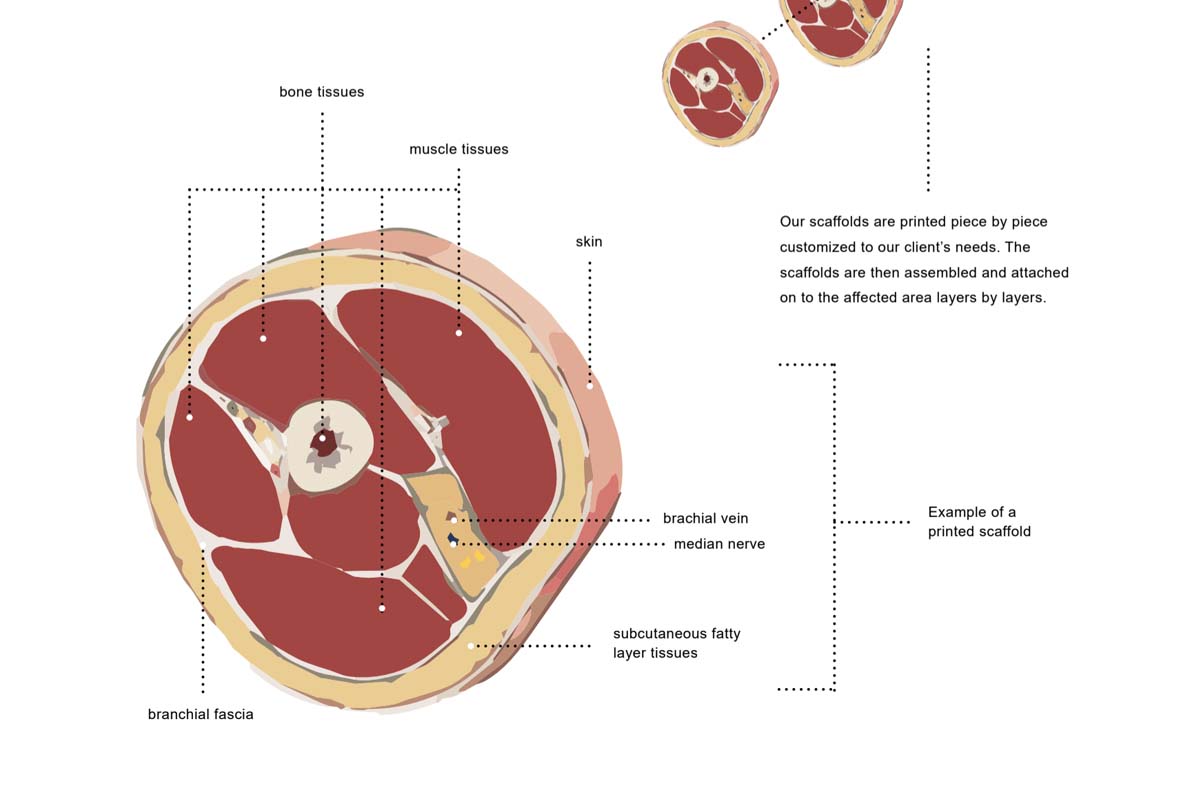

A 3D printed tissue scaffold for natural limb growth which prints every biomaterial at the same time.

Proposal Presentation

The product innovates on current conditions as it doesn’t use real human cells. The mobile app tracks scaffold print progress so you know how long you have to wait. The app also allows you to call/text/schedule doctor appointments.

Final Presentation

Final materials include chitosan for skin, PCL for bone, fibrin for blood vessels, and collagen for muscle.

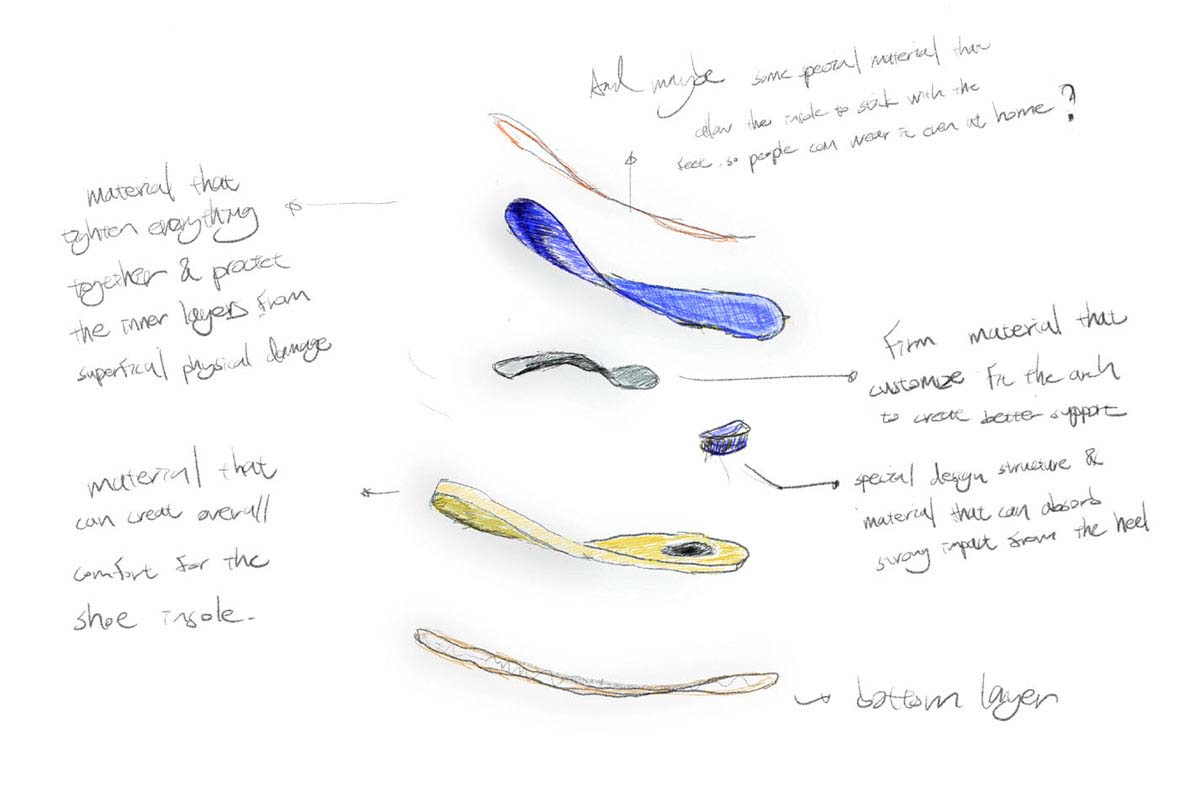

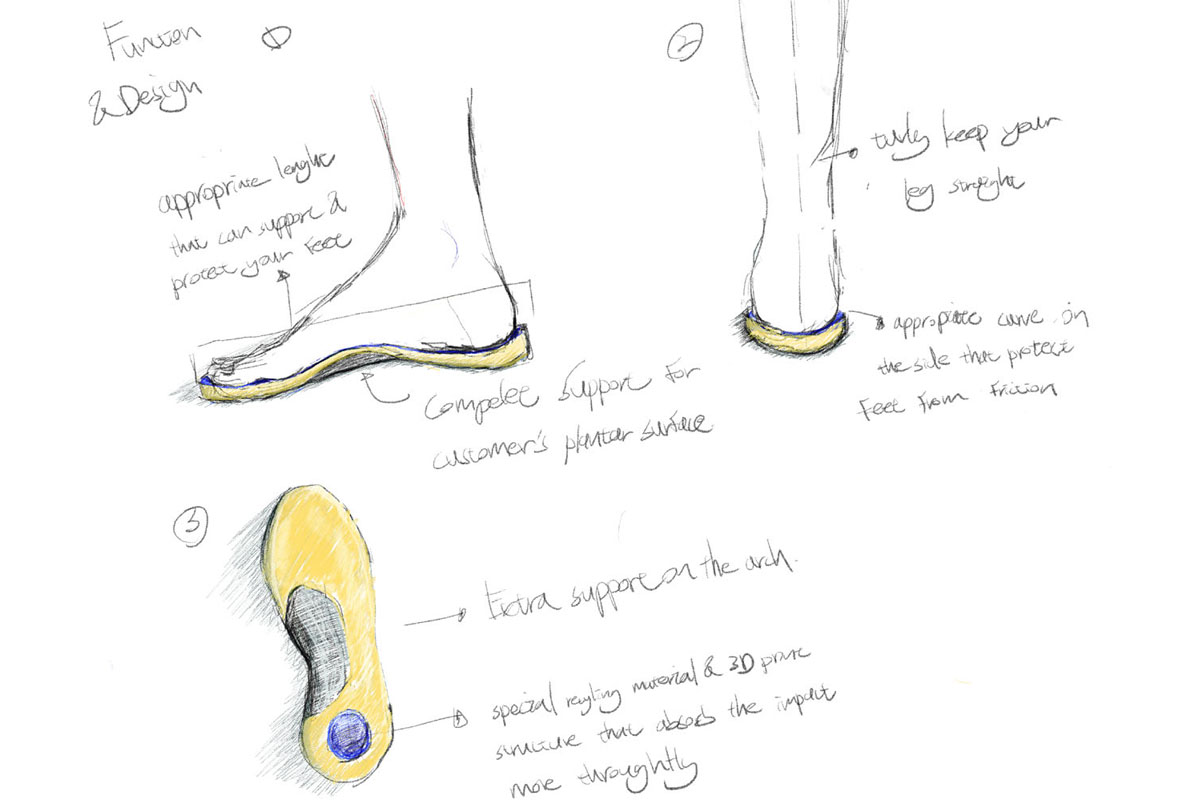

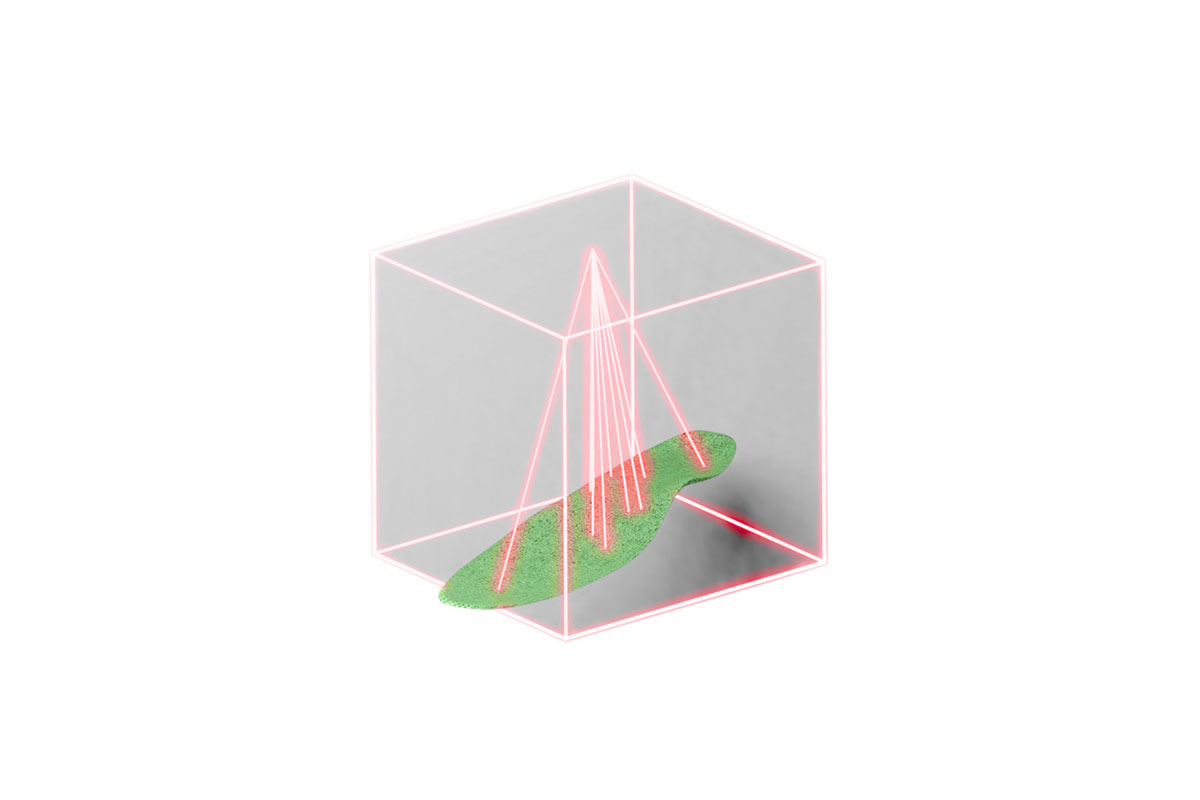

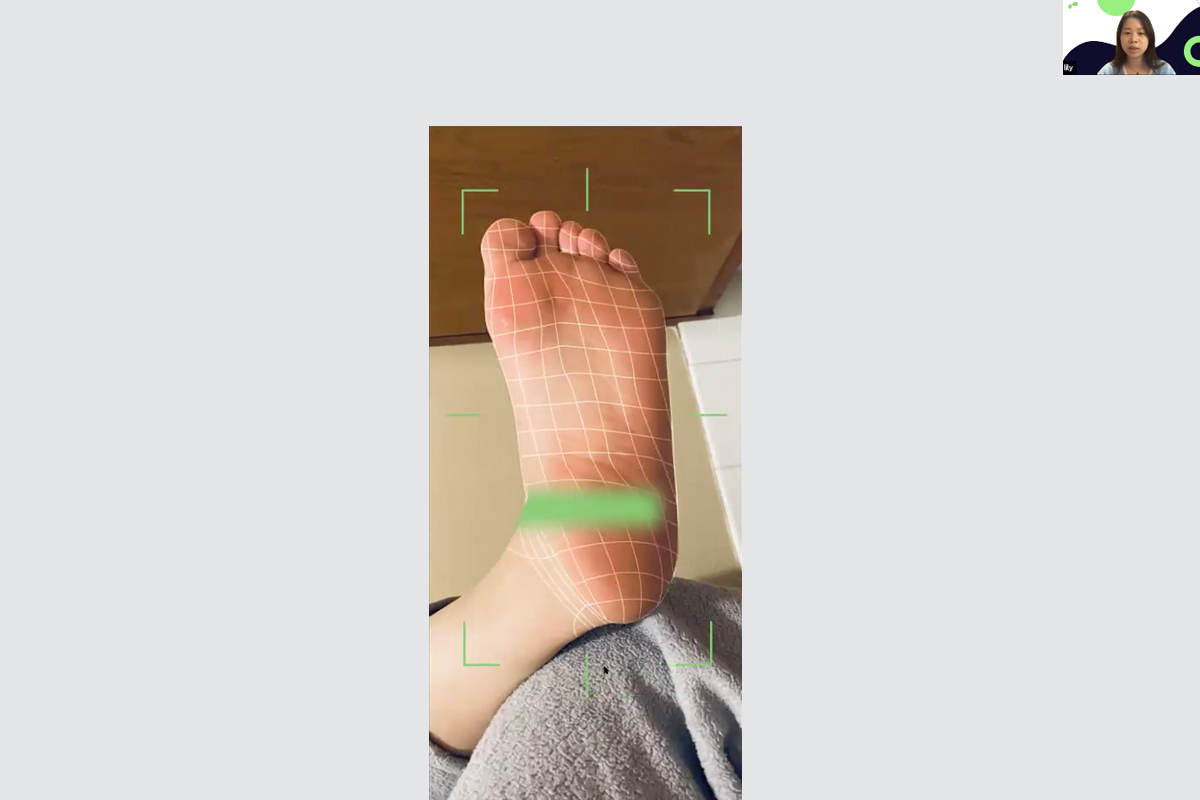

ReSole

Designers

Hung Tsai, Lily Su, Ryan Parajas

Engineers

Jocelyn Orta, Sukhjiwan Singh, Suzanne Estella

3D printed shoe insoles from recycled materials, using 3D LiDAR scanning from phones to accurately calculate foot structure. The goal is to make customizable insoles accessible to everyone.

Proposal Presentation

The insole structure uses multiple layers to support arches and provide airflow to prevent accumulation of sweat.

Final Presentation

ReSole's website promotes the product, while its mobile app allows users to customize and purchase a shoe insole of their own.

Foodie

Designers

Mary Gutierrez, Anela Oliveros, Chako Shinmoto

Engineers

Angela Trans, Jericho Liba, Thomas Bi

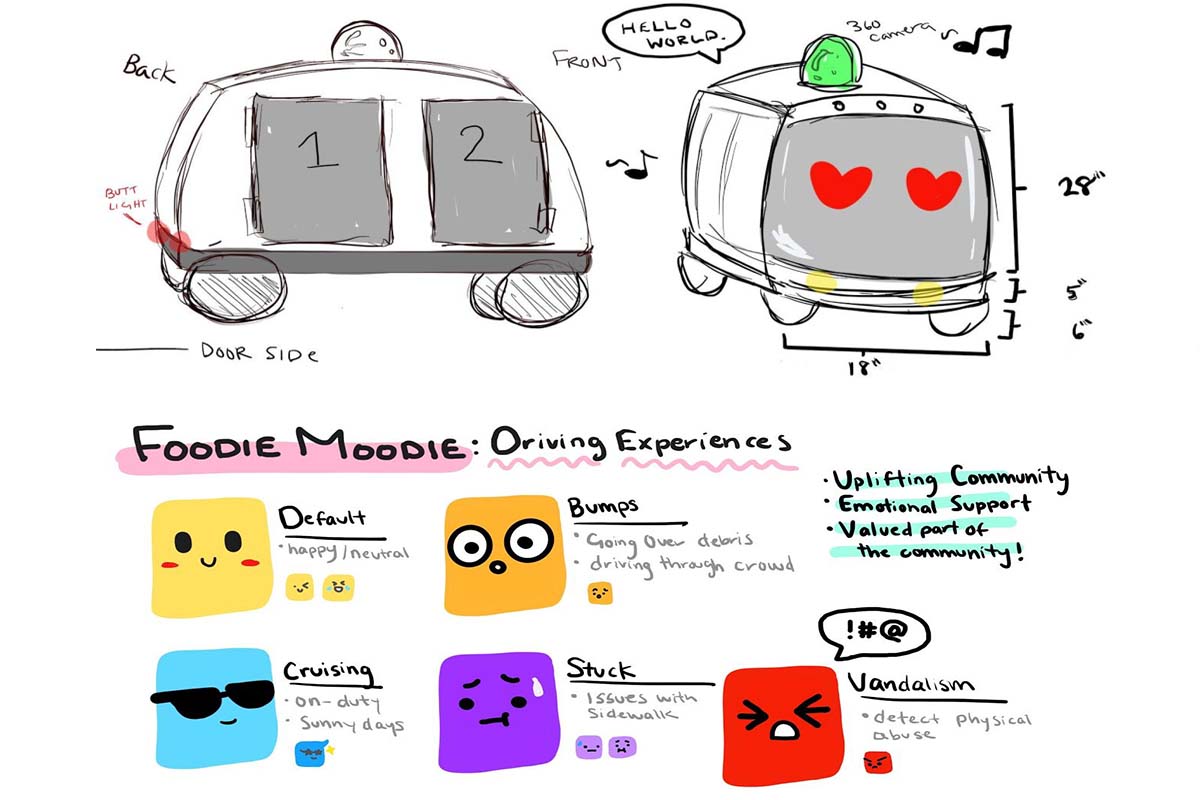

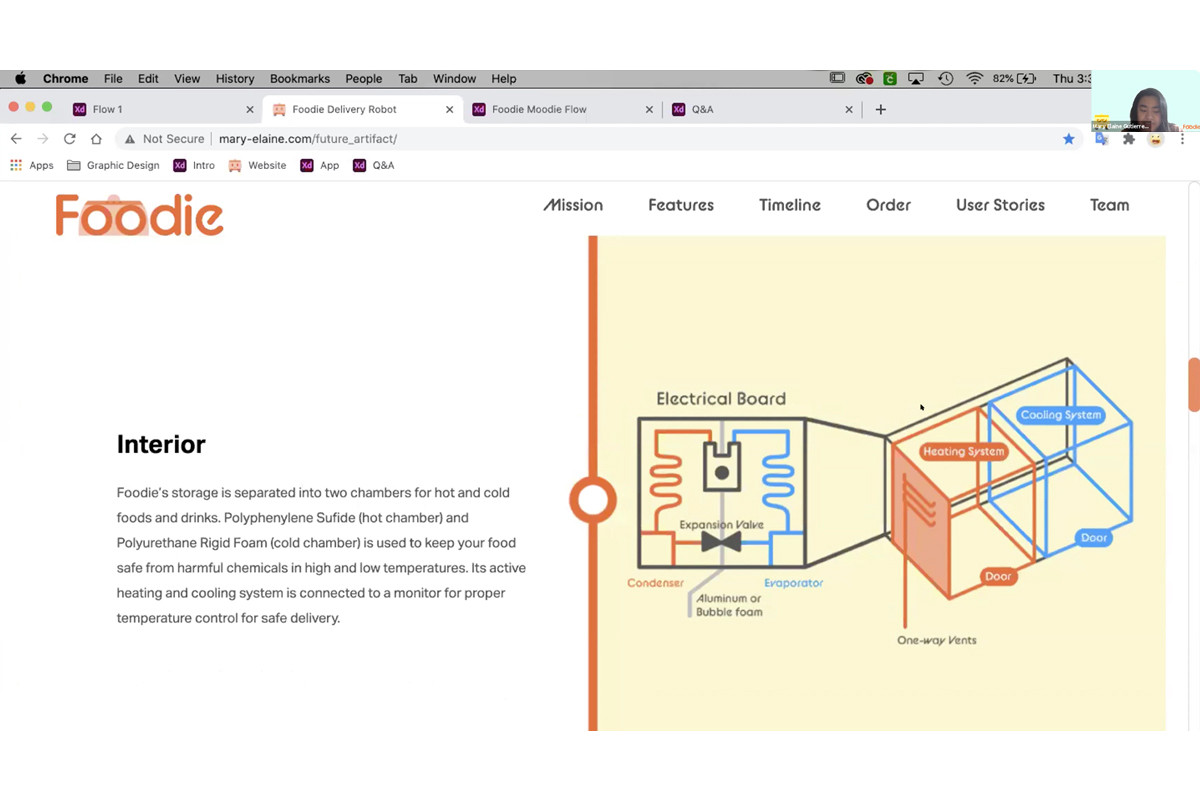

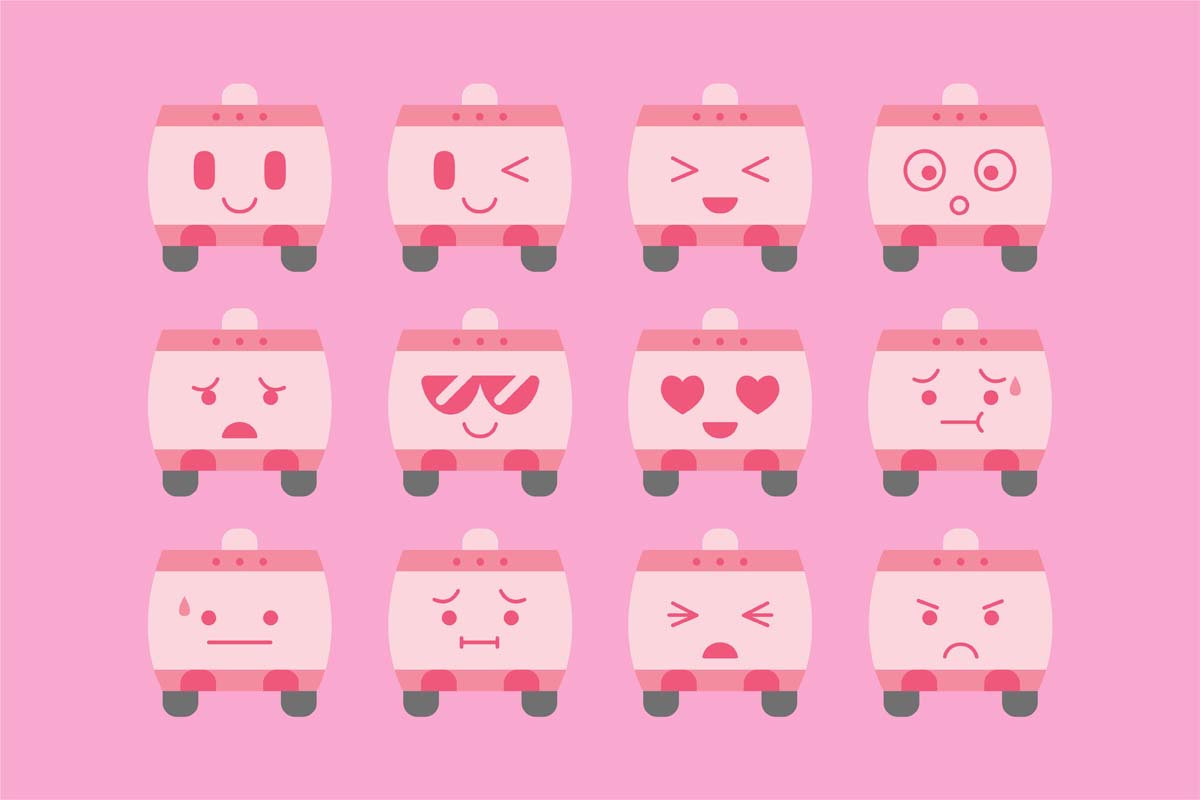

A 24/7 food and drink contactless delivery robot made of a PVC outer shell, a polyphenylene sulfide heating system, and a polyurethane rigid foam cooling system.

Proposal Presentation

Proposed materials for Foodie were PET for the interior and a thermoset for the exterior. A one-way vent is included in the heating system for condensation to escape. The Foodie mobile app will actually control the robot, handling orders and deliveries.

Final Presentation

Final materials are a PVC outer shell to prevent theft, prevent damage, and withstand harsh environments, a polyphenylene sulfide heating system, and a polyurethane rigid foam cooling system.

ecoHUT

Designers

Miguel Morejon, Thanhthao Van

Engineers

Dan-il Yoon, Dan Pham, Kyna Chen

Converts recycled PET (plastic materials from water, juice bottles, etc.) into 3D printable materials for temporary and portable shelters.

Proposal Presentation

The product works like a tent and material must be clear enough to allow daylight to come in. The circular form automatically pops up, so setting up, closing up and putting everything back together can be easy for the user.

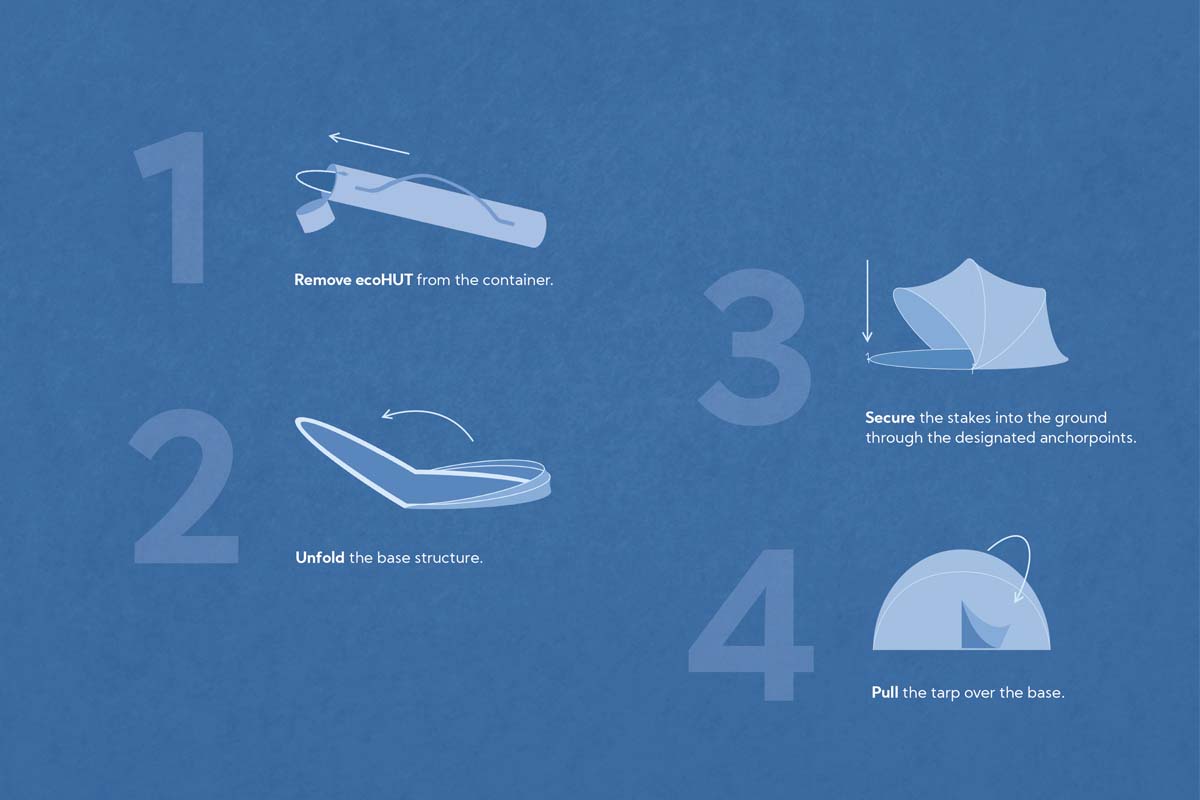

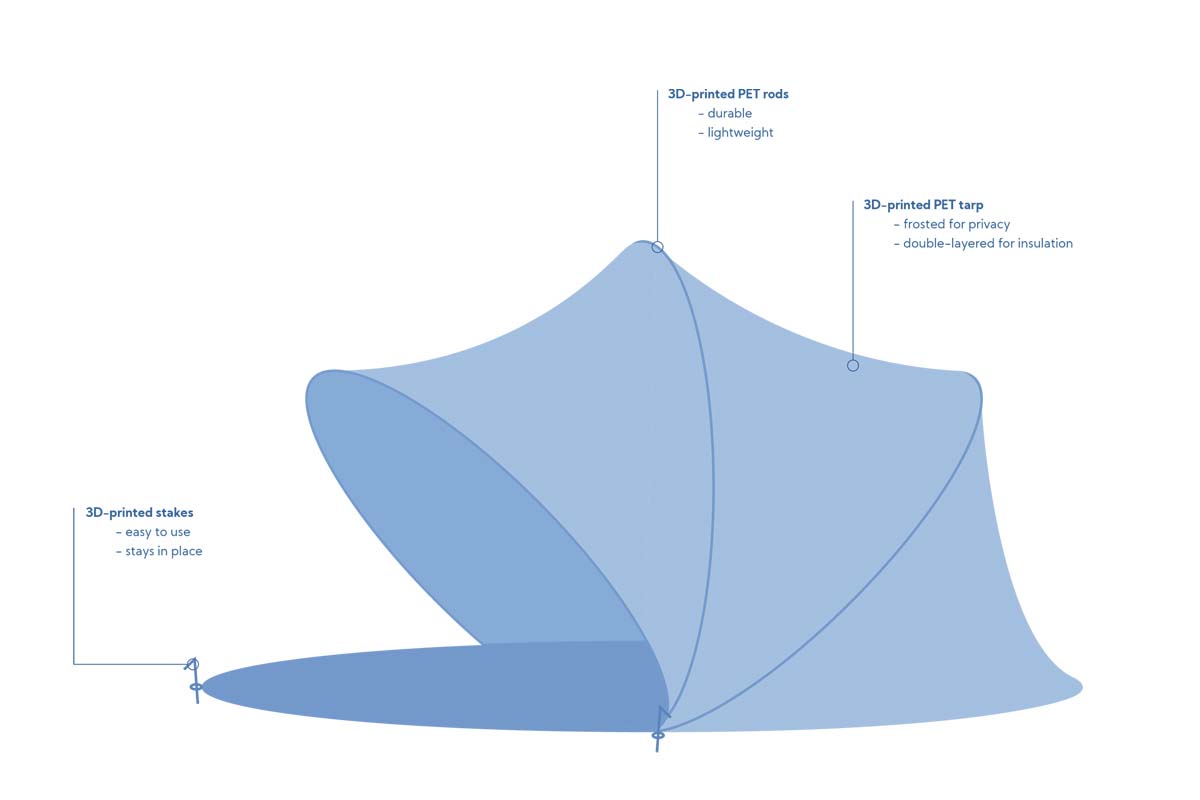

Final Presentation

Drawing inspiration from paper lanterns and handheld fans, ecoHUT is designed to expand and collapse as a single unit consisting of 3 main parts: the curved rods, the tarp, and stakes.

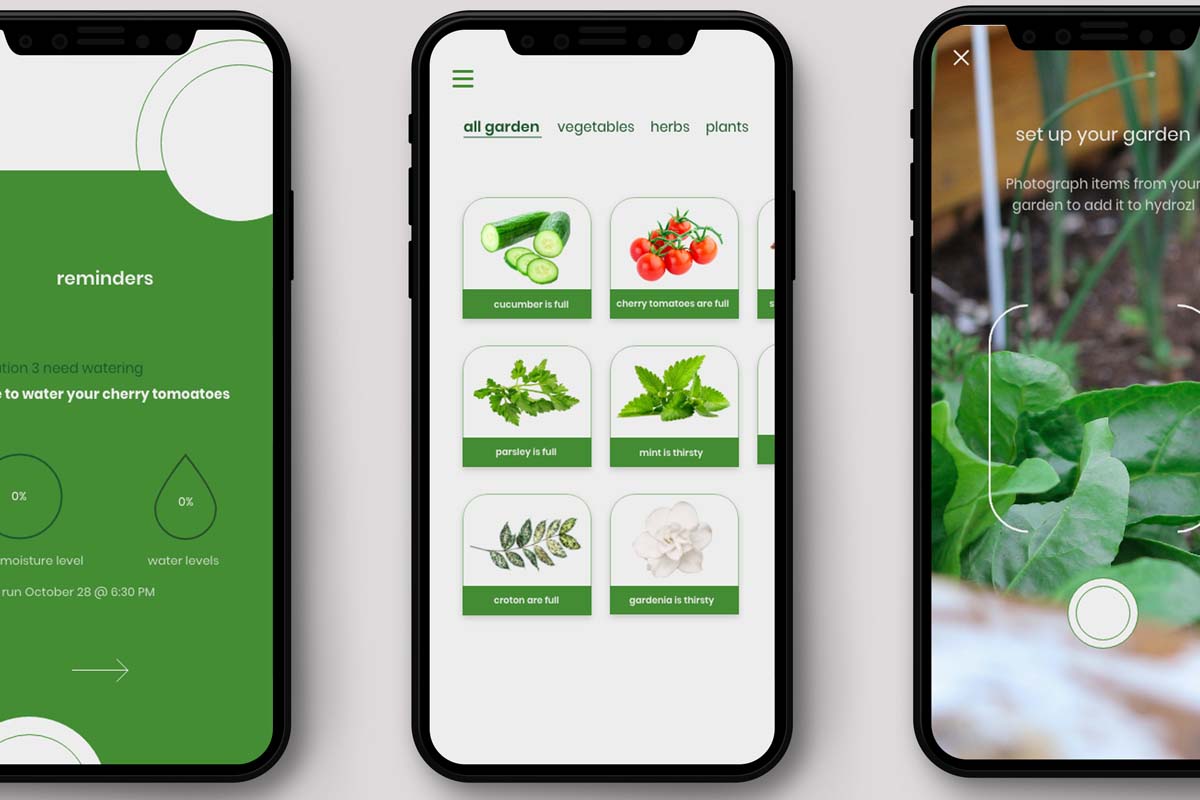

Hydrozl

Designers

Karla Peralta, Dana Nissan

Engineers

Yuritzi Barranc, Dana Morrar, James Shiroishi

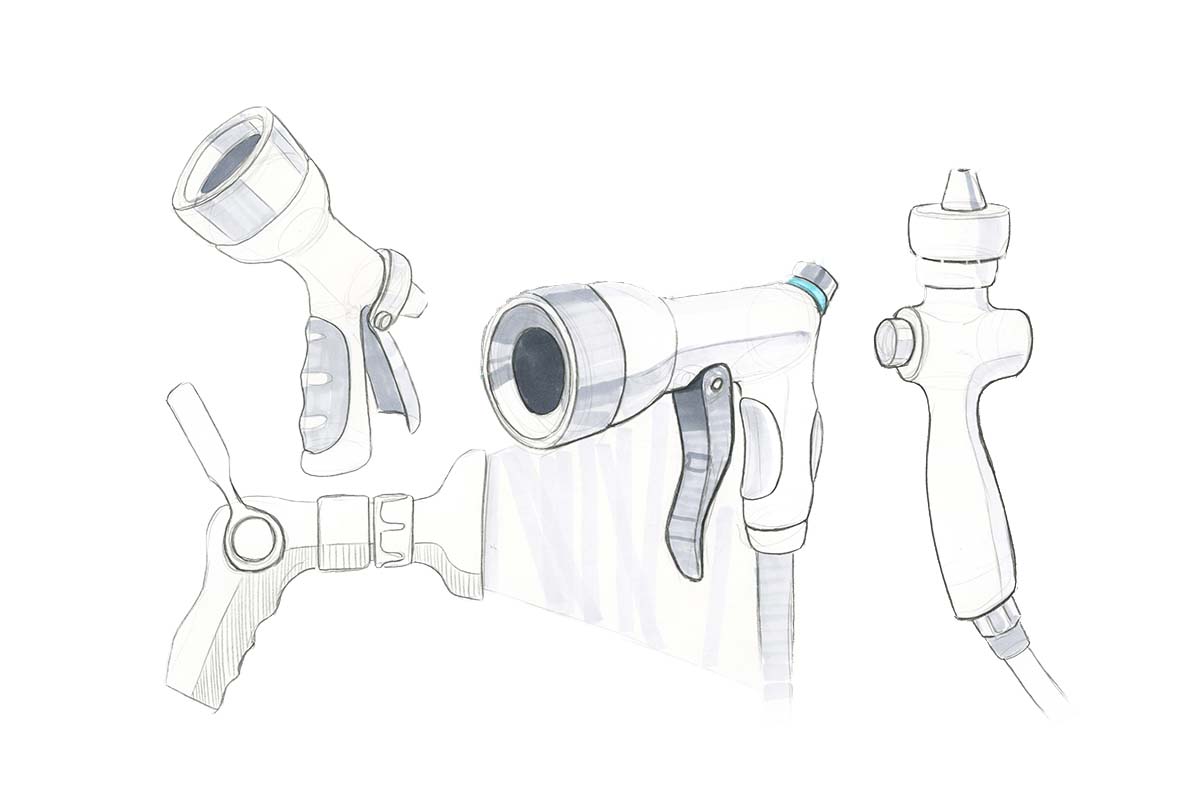

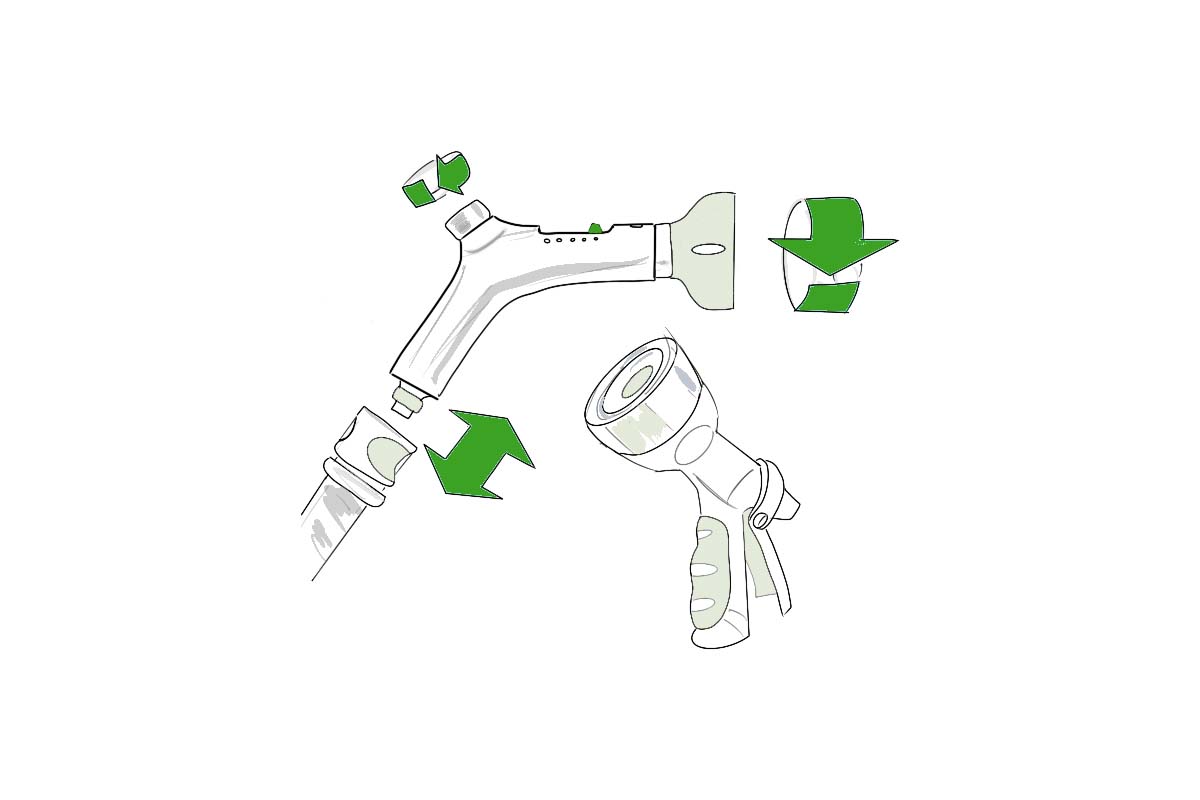

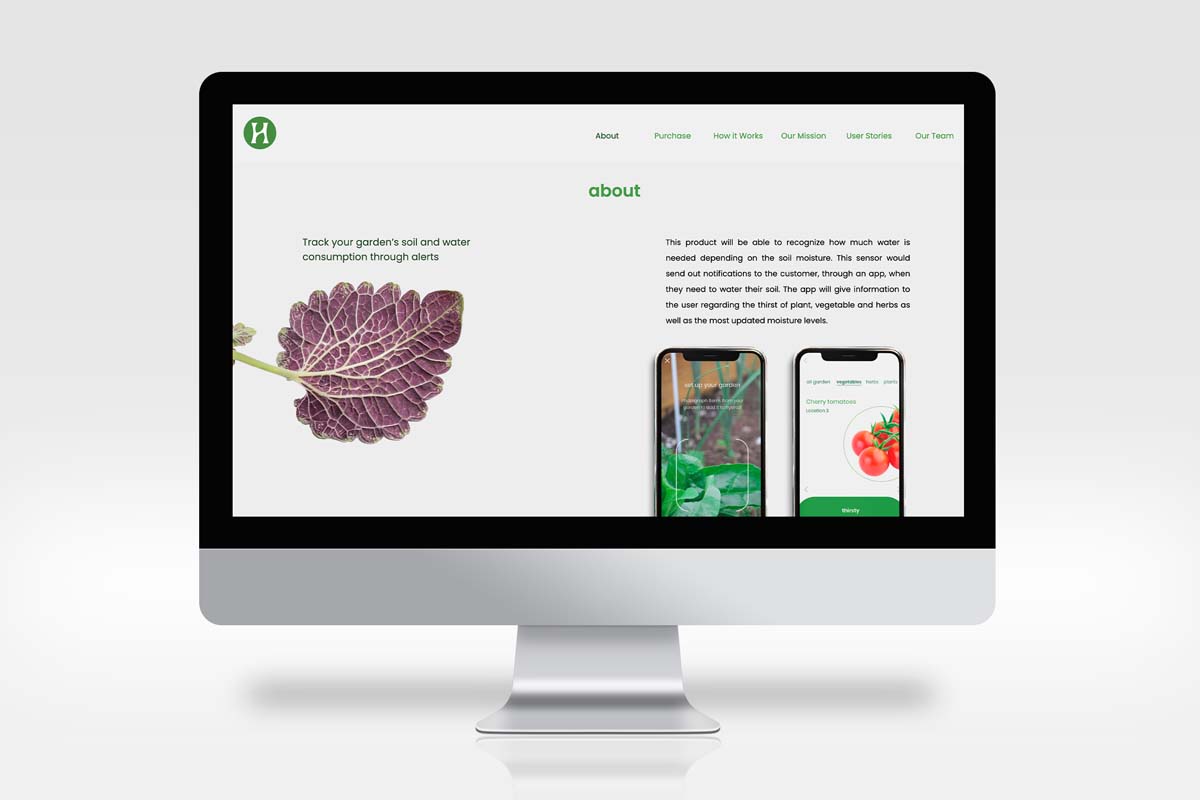

Chip-engineered nozzles made from biodegradable materials, connected to moisture meters that notify people when their soil needs to be watered.

Proposal Presentation

The hose's sensor is connected to soil monitors placed near plants. The hose will start and stop itself to prevent both overwatering and underwatering.

Final Presentation

The nozzle screws into the hose, connects to moisture meters, and then connects to the app itself. The goal is to use environmental materials to help the global water crisis and water irrigation.

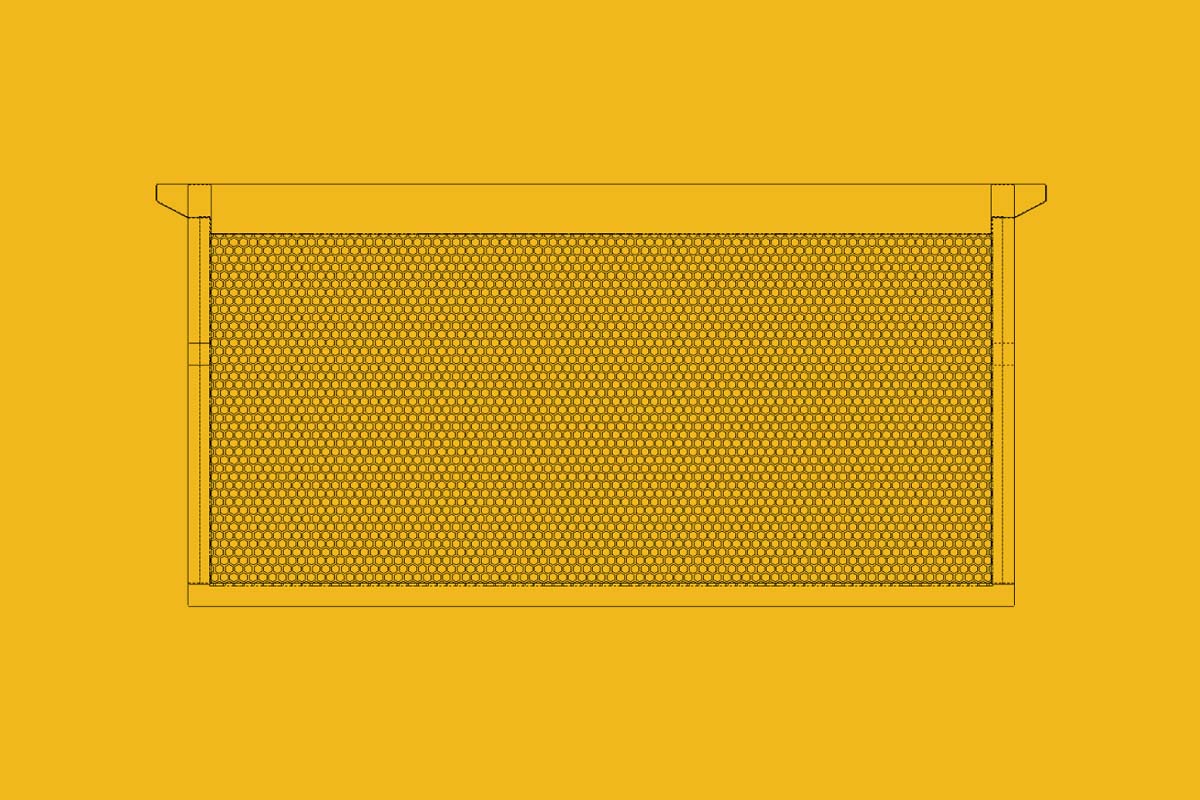

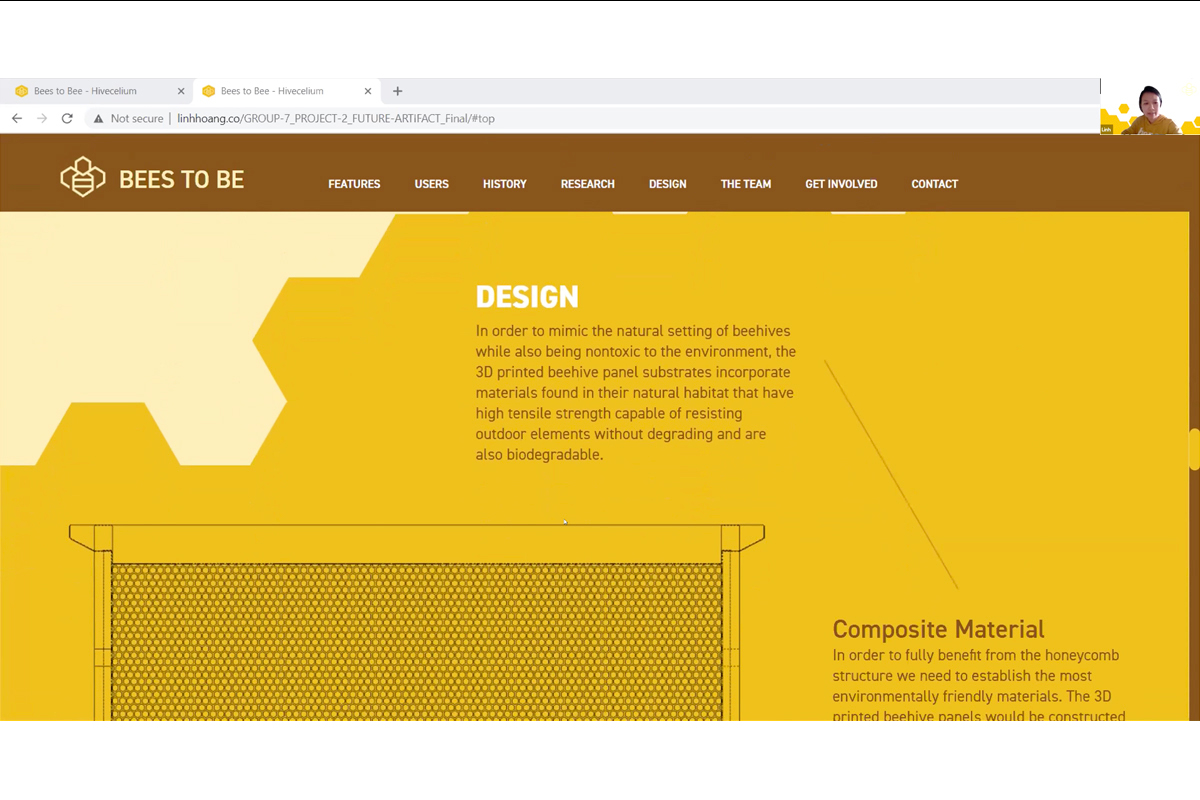

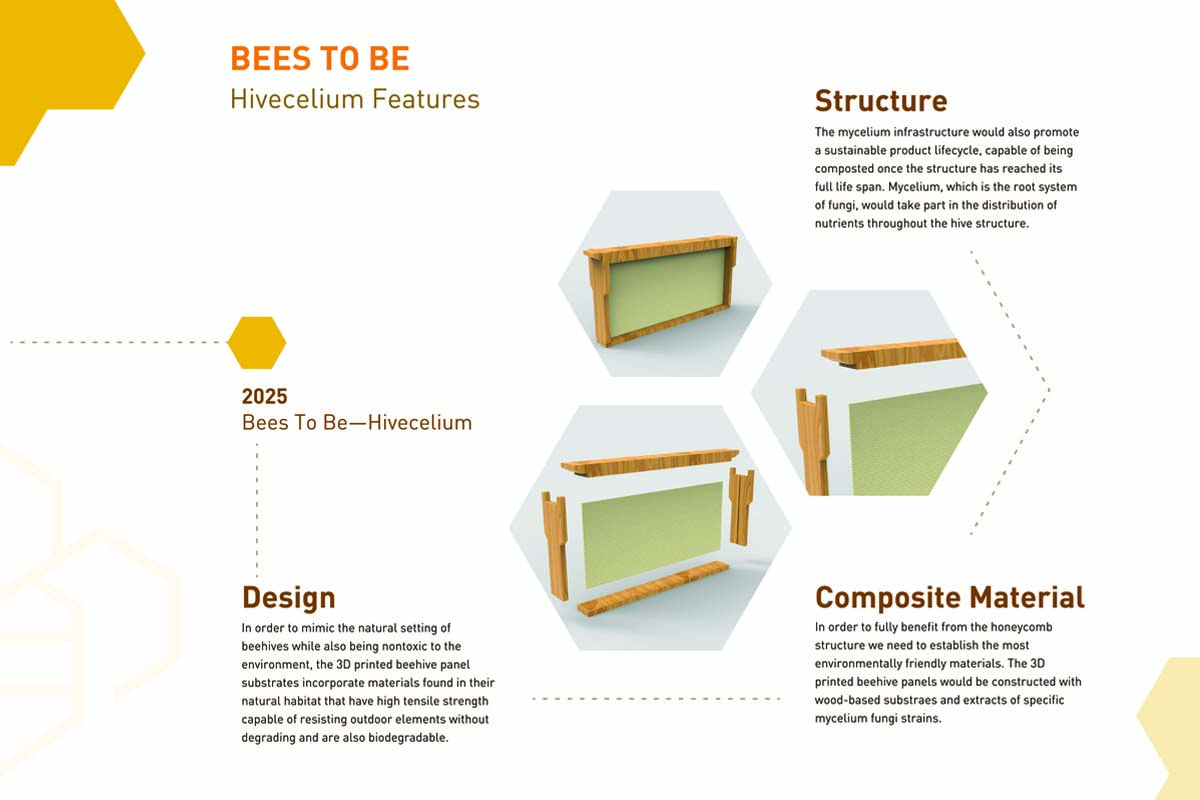

Bees To Be

Designers

Brandon Huynh, F. Lee, Linh Hoang

Engineers

Jia Pelpa, Sharmaine Piros, David Canoy

A biodegradable 3D printed mycelium-based frame implemented in hives to better support hive health and prolong the bee life spand.

Hivecelium: Proposal Presentation

Bees to Be intends to promote the connection between beekeepers and non-beekeepers by giving people the opportunity to sponsor/adopt a professionally installed beehive in local communities.

Final Presentation

Bees to Be promotes a sustainable life cycle capable of being decomposed once the structure reaches the end of its lifespan, which is around 3-5 years.

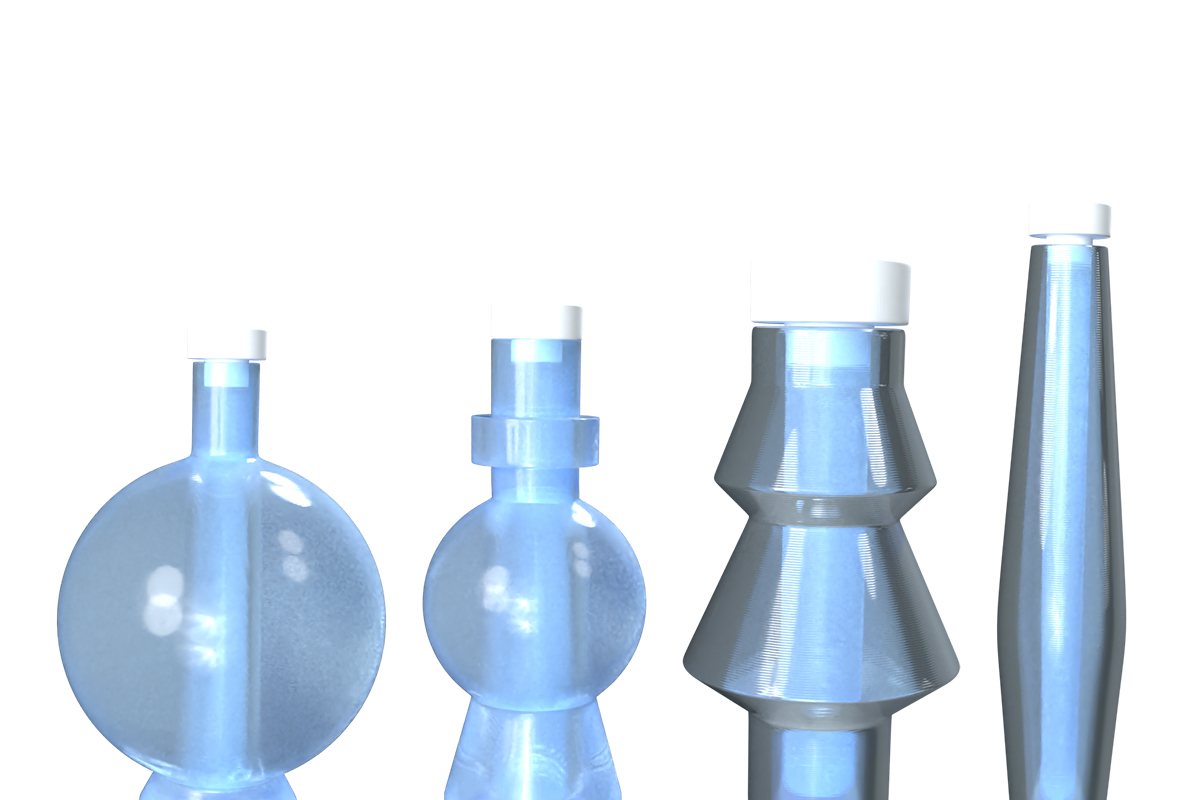

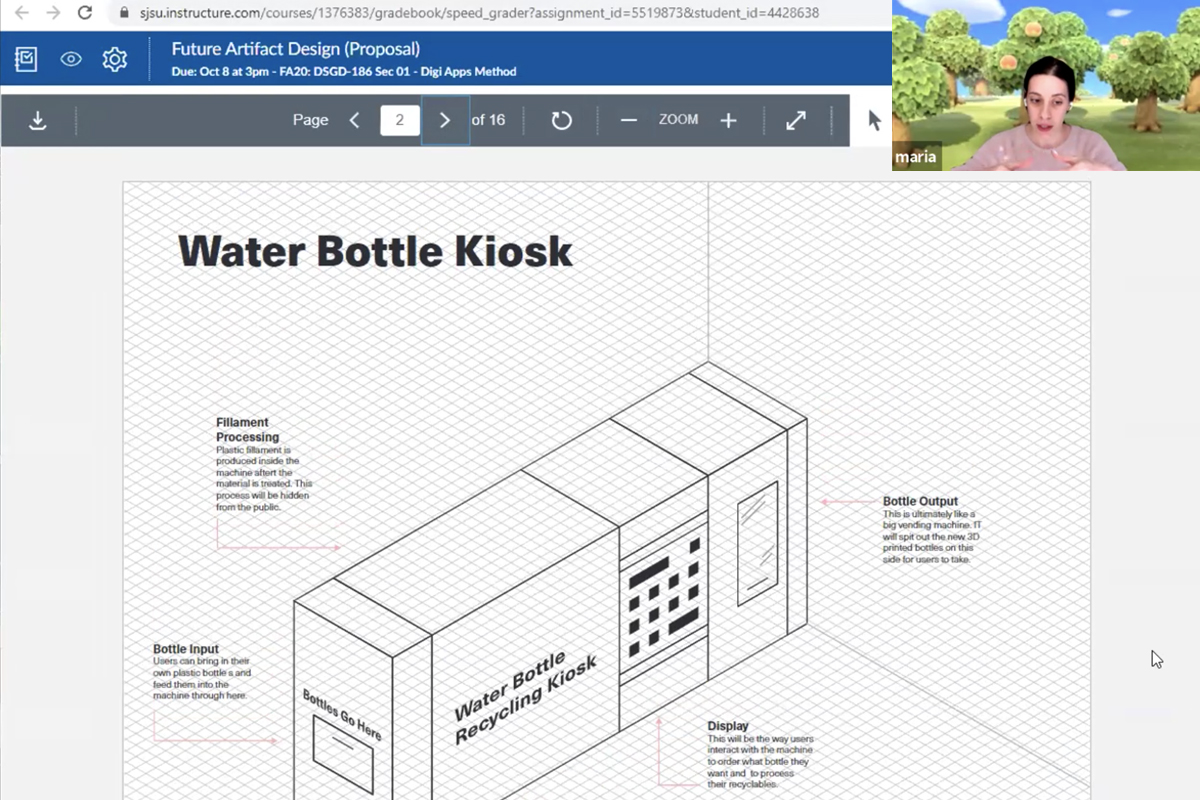

Vottle

Designers

Maria Nieves Ortiz Coll, Diego Areola

Engineers

Treven Hunter, Safiah O'Neill

A kiosk that recycles disposable water bottles, creates a filament and then 3D prints a vacuum-insulated reusable bottle with customizable sizes and shapes.

Proposal Presentation

3D printed water bottle kiosks are not necessarily new, so the innovation focuses on the manufacturing process to make Vottles vacuum sealed. In terms of design, Vottles need to have a wide mouth, and be printed in one piece.

Final Presentation

Vottle addresses the issue of waste reduction, as Vottle kiosks recycle disposable water bottles, creates a filament, and then 3D prints a vacuum-insulated reusable bottle. The Vottle mobile app allows people to personalize, customize, and pre-order Vottles from home.

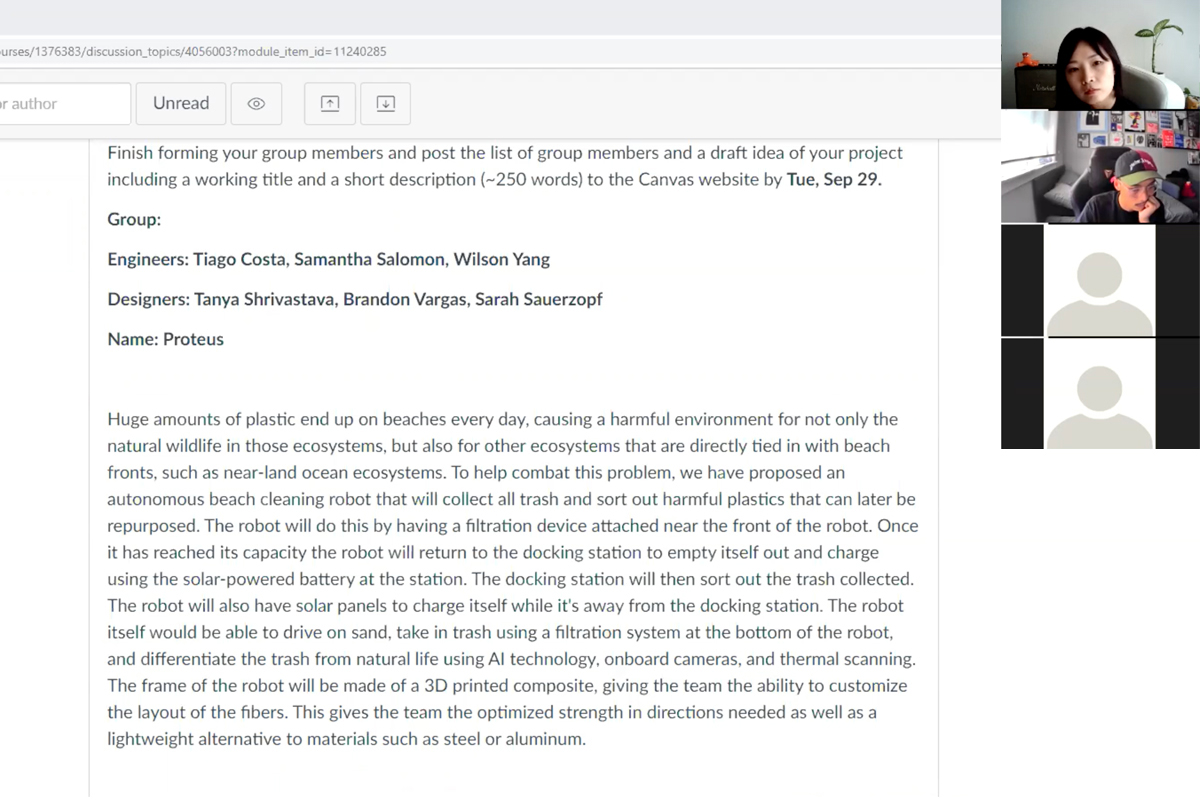

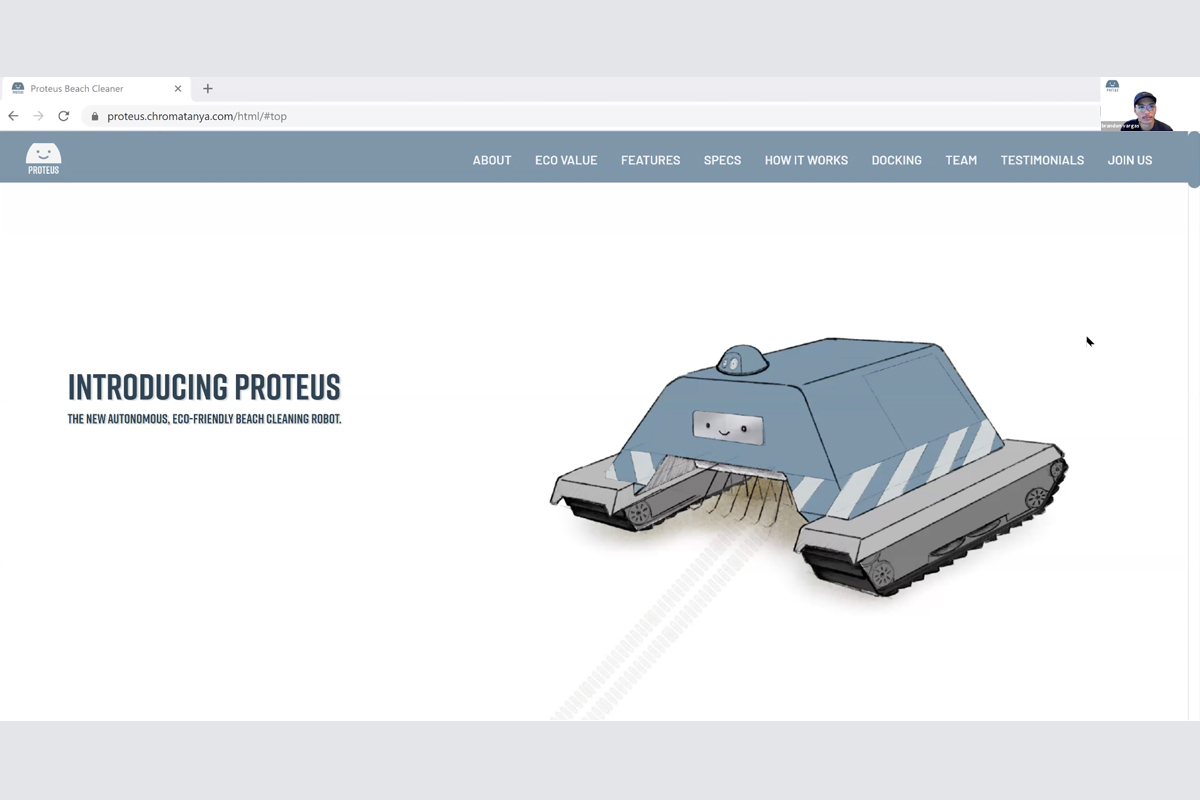

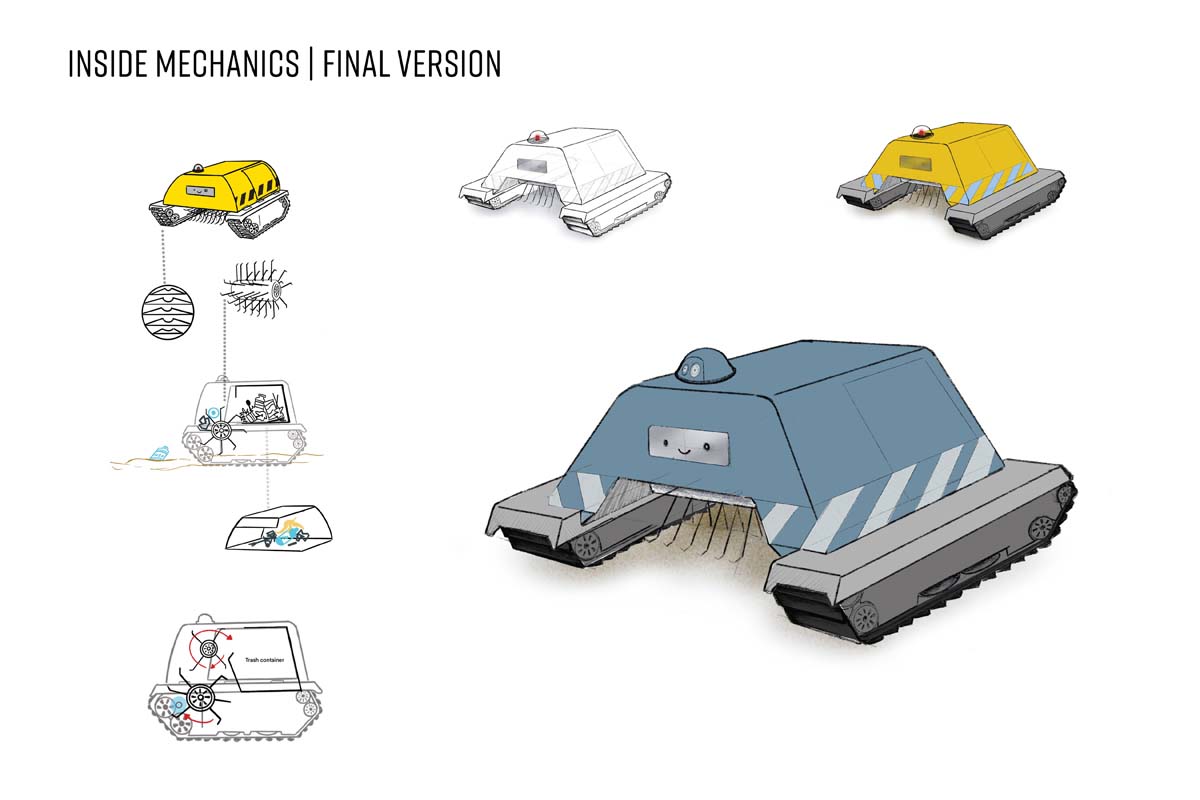

Proteus

Designers

Brandon Vargas, Sarah Sauerzopf, Tanya Shrivastava

Engineers

Samantha Salomon, Tiago Costa, Wilson Yang

An autonomous beach cleaning robot with a 3D printed interior that filters litter from beach grounds for sorting between trash, plastic and miscellaneous materials at docking systems.

Proposal Presentation

Proteus will be fully autonomous rather than man-powered. The solar powered docking station charges Proteus during the day so it can go out and clean later when beaches are closed.

Final Presentation

Proteus will function according to city systems in order to properly process material waste.

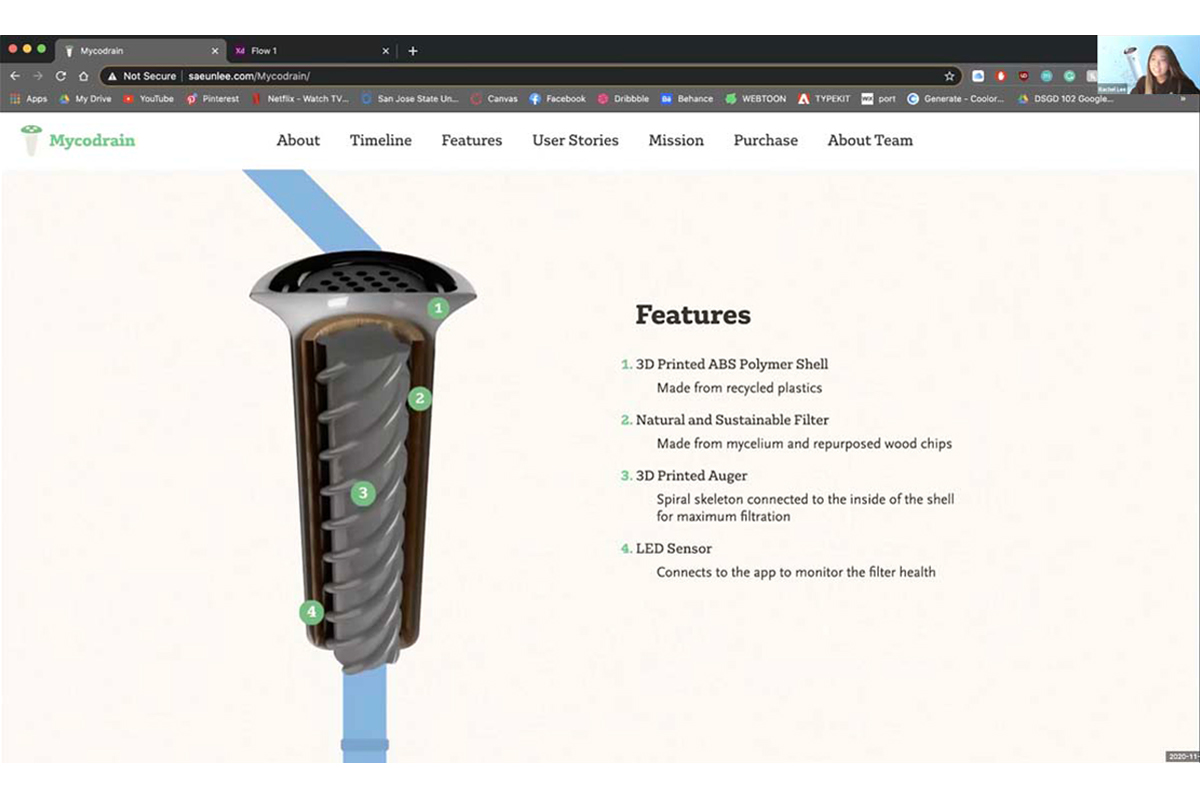

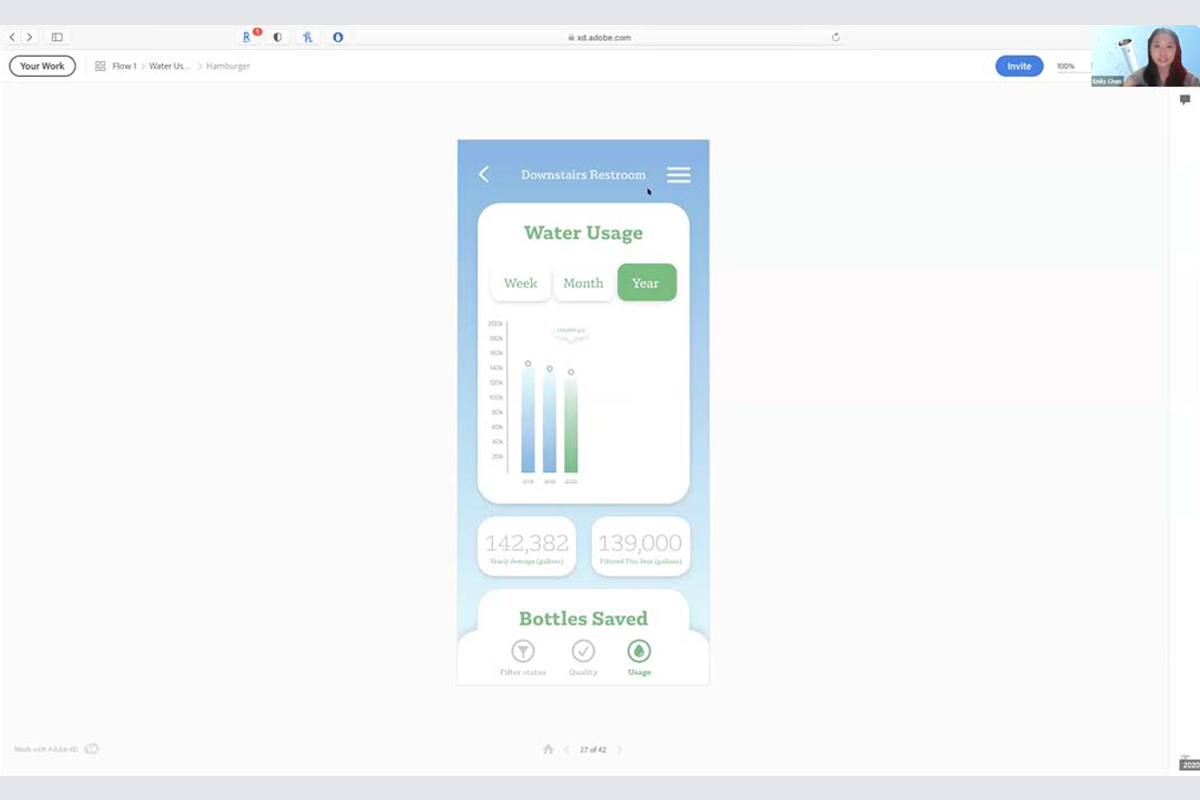

Mycodrain

Designers

Rachel Lee, Emily Chan

Engineers

Eric Comstock, Andy Lam, Cameron

A 3D printed mycelium wood chip biofilter for industrial and storm drain wastewater.

Proposal Presentation

Mycodrain filters industrial/storm drain wastewater with a 3D printed mycelium biofilter. The pipe itself will be 3D printed with recycled plastics. Inside the pipe are biodegradable materials: the actual filtering system of mycelium, and wood chips. The cost should be relatively cheap and accessible to countries without access to fresh water.

Final Presentation

Mycodrain’s mobile app monitors when to change out the filter, and also tracks usage and quality.